Is Fiberglass Insulation Safe for Your Company?

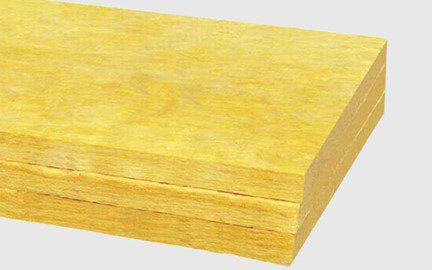

Fiberglass is the most commonly used insulative material in the world. And its popularity is no fluke. Fiberglass is inexpensive, energy-efficient, and relatively safe in fires. But research has shed some light on the possible dangers of fiberglass and many people are beginning to ask, “Is fiberglass insulation safe to use?”

In short, fiberglass is safe to use in most situations. There are countless government agencies devoted to making sure that all of the materials used in building homes and offices are safe.

However, there are some precautions to keep in mind when working with fiberglass. But before we dive into those, let’s learn about the beginnings of fiberglass insulation.

History of Fiberglass Insulation

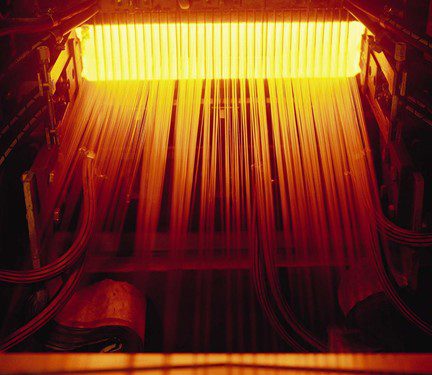

Glass fibers have been produced in various ways for hundreds of years. But it wasn’t until 1932 when Games Slayter discovered that blowing air at molten glass produced fine glass fibers.

This method was refined by Owens Corning in 1935 and mass production began shortly after. Owens Corning is still one of the world’s largest manufacturers of fiberglass insulation to this day.

Fiberglass soon became one of the best and most reliable forms of insulation. Its inexpensive uses in both residential and commercial settings made it a popular choice among homebuilders and construction companies.

In 1965, the U.S. passed a law requiring all new homes to be built with insulation. This new requirement, in addition to the phasing out of asbestos, pushed the popularity of fiberglass insulation even further.

Today, fiberglass is the most popular choice for insulation. A 2018 survey showed that 71% of builders prefer fiberglass insulation over alternatives such as spray foam, cellulose, and wool.

Ways of Manufacturing Fiberglass

Games Slayter’s original method of manufacturing fiberglass through the use of heat and blowing air is still used today. But other methods have been created since then.

One of the most widely used forms of fiberglass manufacturing involves heating glass until it is molten and then forcing it through super fine holes. This method has proven to be a safer and more consistent process than Slayter’s original process.

Once the glass has been made into various lengths of fiber, different resins may be added to increase its strength.

Applications of fiberglass vary widely but include common items such as swimming pools, car parts, and even surfboards!

Is Fiberglass Insulation Safe?

The discussions regarding fiberglass insulation’s safety began in the late 1960s when Dr. Mearl F. Stanton of the National Cancer Institute began studying the health effects of fiberglass.

His research showed that certain sizes of fiberglass were found to be carcinogenic to rats. This finding indicated that similar effects would be applicable to humans.

However, more recent studies have shown that there are no carcinogens in the fiberglass itself but rather in the binders used in the production process. And Dr. Stanton’s research is considered to be outdated.

But it’s important to keep in mind that because a material is safe to be used in the right conditions, this does not mean it is completely harmless.

Fiberglass is a material known to be completely safe at rest. So, walking around a manufacturing plant with exposed fiberglass insulation rolls or an office with visible fiberglass panels would be perfectly acceptable.

The dangers of fiberglass insulation arise when the material is disturbed. The movement of fiberglass will disperse tiny glass particles into the air which have been shown to irritate the skin and lungs if inhaled.

Precautions For Working with Fiberglass

When working with fiberglass, it is important to wear the appropriate safety gear:

- Long Sleeves and Pants: Fiberglass particles can cause irritation to any exposed skin that it comes in contact with. Long sleeves, pants, socks, and close-toed shoes will decrease the points of contact.

- Gloves: It goes without saying that if you need to wear long sleeves to protect against fiberglass, then you should absolutely cover the part of your skin coming in direct contact with the insulation itself.

- Sealed Goggles: Your eyes are a very sensitive part of your body and it’s important to keep microscopic glass fibers out of them! But ensure that the goggles being used are sealed to the face, otherwise, micro sized pieces of glass can still find their way into your eyes.

- Mask: Probably the most important piece of protection against fiberglass particles is a dust-proof mask. While fiberglass is shown to be relatively harmless in short periods, long-term exposure to fiberglass without a mask can cause significant damage to the lungs. A mask should be worn at all times when working with fiberglass insulation.

It should be pointed out that fiberglass has not been labeled as an extremely harmful material by the U.S. or any other government. But this does not mean that precautions don’t need to be taken.

Think of it like this, a broken glass window is anything but safe. Sharp glass fragments can cause large cuts to those who don’t take the necessary precautions. But you don’t need to call a hazardous waste team to clean up broken glass. All you need are gloves, a broom, and some common sense.

Working with fiberglass insulation is very similar. Can it be harmful? Yes. But if you ensure that the necessary safety measures are taken then you will be perfectly fine.

Should Fiberglass Be Contained?

In most cases, fiberglass insulation is going to be contained behind sheetrock walls or between floors. But some types of insulation are designed to be out in the open and this has the chance to cause harm.

As stated above, fiberglass insulation is completely harmless when at rest. It is only when fiberglass is disturbed that it becomes potentially harmful.

This should be considered if you plan to keep fiberglass out in the open.

For example, acoustic insulation panels are frequently made out of a fiberglass blend. These panels can be hung from ceilings, placed on walls, or even be used as desk dividers. This places visitors at risk if they try to touch the panels.

But direct contact isn’t all that’s needed to cause harm. Fiberglass insulation placed near an A/C or fan can be disturbed by the airflow and release dangerous glass particles and chemical binders (such as formaldehyde) into the air.

So, just remember to be cautious if using fiberglass in an open environment. If you are not certain that the placement of fiberglass insulation is safe, then be sure to contact a professional for a second opinion.

Alternatives to Fiberglass

Fiberglass is likely to be the first choice with many builders. But, if the potentially negative effects outweigh the benefits, then there are many alternatives available on the market.

Cellulose

Cellulose is a type of insulation made from recycled materials such as newspapers and cardboard. It is a great alternative to fiberglass.

One of the drawbacks of cellulose is its struggle to wick away moisture. If cellulose insulation gets wet, then you run the risk of mold and mildew growing before it can fully dry.

Another downside is that cellulose is not naturally fireproof. And the chemicals used to make it fireproof can be rather unpleasant to work with.

Wool

Wool can be a great alternative to fiberglass because of its natural insulation properties, ability to wick away moisture, and resistance to fire.

One of wool’s other benefits is that it will keep your house warm in the winter and cool in the summer. Homes with wool insulation see a decrease in their heating bill.

However, be prepared to pay a premium for wool compared to its synthetic competitors.

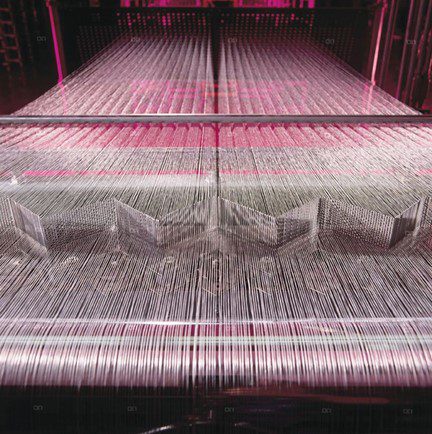

Polyester

In the case of soundproofing insulation, polyester is a great alternative to fiberglass blends. Polyester is completely harmless in all situations, even when in direct contact, and its soundproofing capabilities are able to compete with those of fiberglass.

Our Work with Fiberglass and Alternatives

Our company, Bouckaert Industrial Textiles, has been manufacturing industrial felts since 1988. And one of the main fibers used in these industrial felts is fiberglass.

However, in 2010 we noticed the trend towards companies looking for a safer alternative to fiberglass and so we began researching alternatives.

Our research showed that polyester was one of the best, most affordable, and safest alternatives to fiberglass. Polyester also offers further flexibility in regard to aesthetics like color and molded shapes that are more pleasing to today’s modern interior designers. Today, our line of Poly-Sonic acoustic felt panels are made out of 100% polyester.

While we do still manufacture fiberglass in cases where there is no viable alternative, we have taken large steps towards ensuring our manufacturing process is absent of the dangerous chemical binders which make fiberglass so unsafe.

For companies interested in abating sound in their commercial or industrial spaces, consider using our line of 100% polyester acoustic panels.