How Felt Filtration Plays a Part in Garbage Incineration

We all know that our waste goes into landfills, but there are many important parts of the process that you may not know. While discussions about sustainability and waste reduction frequently revolve around recycling and composting, felt filtration for garbage incineration often remains overlooked. This process plays a vital role in modern waste management by capturing harmful pollutants from incinerator emissions, promoting a cleaner and more environmentally friendly approach. Even though it is often forgotten, garbage incinerator filtration greatly prevents negative environmental effects.

Garbage incinerator filtration concerns a term called Municipal Solid Waste (MSW). MSW refers to the solid waste generated by households, commercial establishments, institutions, and other non-industrial sources within a community. This type of waste can range from glass to textiles, to food scraps. Municipal solid waste poses a significant environmental threat for various reasons. When deposited in landfills, it undergoes decomposition and releases methane, a potent greenhouse gas that contributes to climate change. Decomposing waste also contains harmful chemicals that can contaminate soil and water sources, posing risks to ecosystems and human health. Improperly managed solid waste also leads to habitat destruction and wildlife endangerment, as landfills encroach upon natural areas. Fortunately, technologies like felt filtration for garbage incineration can help address many of these negative environmental impacts.

Garbage incineration, a method employed in waste management, involves the combustion of MSW to reduce its volume and control environmental hazards associated with landfills. While incineration offers several benefits such as volume reduction, energy recovery, and decreased reliance on landfills, it also presents challenges in terms of emissions and air pollution control. For more information on how and why incinerators are beneficial check out Life Cycle Assessment of Municipal Solid Waste Incineration with Energy Recovery.

Garbage incinerators produce various pollutants during combustion, including particulate matter, heavy metals, acidic gases, and organic compounds. To lower the environmental impact of these emissions, effective filtration systems are essential, which is where incinerator filtration comes in. Garbage incinerator filtration is the process of removing harmful substances from the exhaust gases produced during incineration, which helps prevent harmful effects during the process.

The filtration process typically involves multiple stages designed to capture different pollutants. Particulate matter, for instance, is often removed using mechanisms such as “electrostatic precipitators” or fabric filters, which trap solid particles as the exhaust gases pass through.

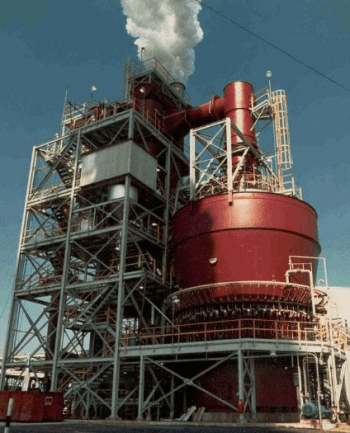

Garbage incinerators come in various forms, each tailored to meet specific waste management needs and operational requirements. These different types of incinerators offer diverse approaches to waste combustion, energy recovery, and emission control, reflecting the versatility and adaptability of waste-to-energy technology. Here are some of the most common types of garbage incinerators:

Mass Burn Incinerators

Mass-burn incinerators are among the simplest and most common types of waste-to-energy facilities. They combust mixed municipal solid waste (MSW) without prior sorting or preprocessing, reducing the volume of waste and generating heat or electricity. Mass burn incinerators typically utilize a furnace with a grate system to support and ignite the waste, followed by combustion chambers and boiler systems for energy recovery.

Modular Incinerators

Modular incinerators are compact, prefabricated units designed for decentralized waste management applications. These modular systems offer flexibility and scalability, making them suitable for small communities, remote areas, or specialized waste streams. Modular incinerators can be easily transported and installed, providing a convenient solution for on-site waste treatment and energy generation.

Fluidized Bed Incinerators

A fluidized bed incinerator is a type of waste management facility used for the combustion of solid waste materials. In this incineration process, solid waste is burned in a bed of inert material, such as sand or ash, suspended by a stream of air or gas. The airflow through the bed creates a fluid-like motion of the particles, hence the term “fluidized bed.”

The key feature of fluidized bed incinerators is their ability to maintain a uniform temperature and efficient combustion due to the intimate contact between the waste particles and the oxygen-rich air or gas. This ensures thorough burning of the waste materials, minimizing the formation of harmful by-products such as dioxins and furans.

Fluidized bed incinerators are known for their flexibility in handling various types of waste, including hazardous and medical waste, as well as biomass and sewage sludge. They are often preferred for their high combustion efficiency and low emissions of pollutants, making them a relatively environmentally friendly option compared to traditional incineration technologies.

The Role of Felt Filtration in Fluidized Bed Incineration

A felt filtration material can be highly useful in a fluidized bed incinerator for capturing particulate matter and other solid pollutants from the exhaust gases produced during combustion. (Best Practices for Fabric Filter Operation and Maintenance for Municipal Solid Waste Incineration Facilities)

Here’s how felt filtration material can be beneficial in this context:

High Efficiency Filtration

Felt filtration materials, typically made from synthetic fibers like polyester or polypropylene, offer a high surface area and intricate network of fibers. This structure enables them to effectively capture fine particulate matter, ash, and other solid contaminants present in the flue gas stream generated by the incineration process.

Resistance to High Temperatures

Fluidized bed incinerators operate at elevated temperatures to ensure efficient combustion of waste materials. Felt filtration materials are designed to withstand high temperatures, making them suitable for use in such environments without compromising their filtration efficiency or integrity.

Flexibility and Adaptability

Felt filtration materials can be tailored to specific filtration requirements by adjusting parameters such as fiber density, thickness, and surface treatment. This flexibility allows for customization to optimize filtration performance and meet the needs of different incineration processes and waste compositions.

Ease of Maintenance

Felt filtration materials are generally durable and resistant to abrasion, prolonging their service life in demanding applications like fluidized bed incinerators. Also, they are easy to clean and maintain, contributing to the efficiency and reliability of the filtration system.

Cost-Effectiveness

Compared to some alternative filtration materials, felt filtration materials often offer a cost-effective solution for capturing particulate matter in fluidized bed incinerators. Their durability, efficiency, and ease of maintenance make them a practical choice for long-term use in waste management facilities.

When dealing with garbage incineration, the role of filtration materials like felt is extremely important. Felt filtration materials offer a high-efficiency solution for capturing particulate matter and solid pollutants from the exhaust gases generated during combustion. Their temperature resistance, flexibility, and cost-effectiveness make them indispensable components of fluidized bed incinerators and other waste-to-energy facilities.

However, it’s crucial to emphasize the importance of sourcing filtration materials from reputable manufacturers. Choosing the right manufacturer ensures the quality, reliability, and performance of the felt used in incinerators. By partnering with experienced manufacturers who adhere to stringent quality standards, waste management facilities can optimize their filtration systems, minimize downtime, and enhance environmental compliance.

In essence, the selection of filtration materials like felt is a critical aspect of maximizing the efficiency and sustainability of garbage incineration processes. By investing in quality filtration solutions and partnering with trusted manufacturers, we can harness the full potential of garbage incineration as a cornerstone of modern waste management practices.

Bouckaert Industrial Textiles is here to help you engineer the best product to meet your needs. If you would like to know how BIT can provide you with high-quality felt for your filtration needs, get in touch today!