What is Cure-In-Place-Piping (CIPP)? And why does a felt manufactuer have anything to do with it?

In the world of pipeline rehabilitation, cure-in-place piping (CIPP) has emerged as a revolutionary solution. This trenchless method has gained significant popularity due to the many benefits it provides, the most important being eliminating the need for costly and disruptive pipeline excavations. Many tools and materials are utilized in the process of cure-in-place piping, but the material that makes the magic happen is the felt lining that creates the repair for the already-existing pipe. In this comprehensive guide, we delve into the fundamental aspects of CIPP, the technology it utilizes, and why felt is so important to this process.

For those visual learners here is a quick introductory video from NASSCO (the CIPP/trenchless trade association). For more depth, keep reading!

What is CIPP?

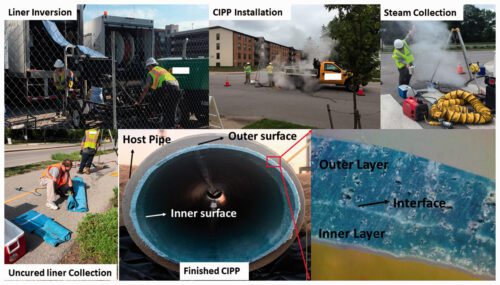

The focus of CIPP is to repair damaged pipelines without the need for complete replacement and costly excavation. CIPP is primarily employed in sewer and wastewater systems but could be used elsewhere. The process of CIPP involves inserting a liner with a thermosetting resin into the existing pipeline. This liner will conform to the shape and size of the pipe, and it is then saturated with resin. The liner is inflated using water or air pressure to press the liner against the walls of the existing pipe. The resin is then cured using heat or ultraviolet light, which essentially creates a new pipe inside the old pipe. This cured liner provides a smooth and durable interior surface that can restore the flow capacity and structural integrity of the pipeline.

What are the benefits of CIPP?

CIPP is a relatively new technology, and there are many benefits that have caused its surge in popularity.

Cost-Effectiveness

CIPP is significantly more cost-effective than other repair methods. CIPP eliminates the need for extensive digging, which reduces labor costs and expenses associated with restoring the excavated area. Additionally, the shorter project duration and reduced downtime contribute to cost savings.

Minimal Disruption

CIPP is a trenchless technology, meaning it requires minimal excavation or disturbance to the surrounding environment. This makes it particularly appealing in densely populated regions, urban areas, or locations with sensitive ecosystems.

Faster Installation

CIPP offers faster installation times compared to traditional methods. Once the liner is inserted into the host pipe, the curing process can be completed relatively quickly.

Versatility

CIPP can be applied to many types of pipes since it is suitable for a wide range of pipe materials, diameters, and configurations. This versatility makes CIPP an attractive option since it provides a flexible solution for rehabilitating several types of pipelines.

Longevity and Durability

The cured-in-place liner creates a new layer within the existing pipe, which enhances its strength and durability. The liner is typically resistant to corrosion, abrasion, and chemical degradation, prolonging the pipeline’s lifespan.

Environmental Benefits

The process of CIPP reduces soil disruption, minimizes the release of pollutants, and conserves natural resources. Additionally, CIPP eliminates the need for transporting and disposing of old pipes, further reducing carbon emissions and waste generation.

Why has CIPP grown so popular?

The growth in popularity of CIPP is due to the advanced technology that allows the process to have many benefits among other rehabilitation methods. From the materials used in CIPP to how the process is performed, these differences put CIPP ahead. Installation techniques like inversion, pull-through, and lateral lining have been refined to ensure accurate placement and eliminate errors. Quality control and inspection technologies further eliminate any room for error to create a more seamless process. These technologies can include things from robotic crawlers to cameras and sensors. Additionally, materials used in the process allow for the durability and longevity of CIPP repairs. Advancements in UV light curing technology have allowed for faster curing times, further speeding up the process.

However, the most important aspects of CIPP are the precise lining and the resin used to solidify it. Improvements made in the resin technology also allow for faster curing times, but more importantly, this ensures better adhesion to the host pipe. This is important because it strengthens the final product. Finally, the blend of high-quality liner materials is the most important aspect of the CIPP process. Different blends of materials are created to perform different tasks within the repair. This depends on the preferred performance of the repair. The ability to formulate different blends specific to repair goals significantly adds to the versatility of CIPP repairs.

What type of felt is used in this process?

There are many blends of material that can be used for CIPP, but the specific type of felt liner chosen depends on the application, pipe diameter, and project requirements.

Polyester Felt Liner: Polyester felt liners are widely used in CIPP applications. They are made from non-woven polyester fibers that are needle-punched to create a durable and flexible material. They offer excellent strength, stability, and resistance to chemicals and abrasion. These felt liners are suitable for various pipe sizes and provide reliable structural reinforcement.

Fiberglass Felt Liner: Fiberglass felt liners consist of a non-woven mat of fine fiberglass fibers that can be bonded together using resin or fiberglass mechanical needling. Fiberglass felt liners are known for their high strength and resistance to corrosion and chemicals. They provide excellent structural support and are often used in larger-diameter pipe rehabilitation projects.

Blended Felt Liner: Blended felt liners are a combination of different fibers, such as polyester and fiberglass. These liners utilize the strengths of each material, providing a balance between strength and durability. Blended felt liners offer improved performance characteristics and are often chosen for challenging pipe rehabilitation projects.

How do I choose the correct CIPP felt lining manufacturer?

Choosing the right lining material for your CIPP needs depends on your specific goals and expectations for your repair. Making sure you choose a felt manufacturer that can create high-performance blends is extremely important to ensure the job gets done correctly.

For over three decades, Bouckaert Industrial Textiles has established itself as a trusted manufacturer of nonwoven felt. At BIT, we manufacture custom needle punch nonwoven felt, as well as three types of CIPP liners starting at 6 ounces per square yard and 1 millimeter thick and going as high as 75 ounces per square yard and ½ inches thick. We are committed to helping our customers create the materials to meet their needs!

Situated in Rhode Island, our plant can produce a diverse range of felt products, thanks to our commitment to custom manufacturing. Everything is made in the USA, and our customers will experience no supply chain interruptions while receiving top-quality materials.

Whichever blend of high-quality materials is needed to meet your goals, we can help you manufacture it.

Have questions or want to source materials from Bouckaert Industrial Textiles for your CIPP application? Reach out to us!